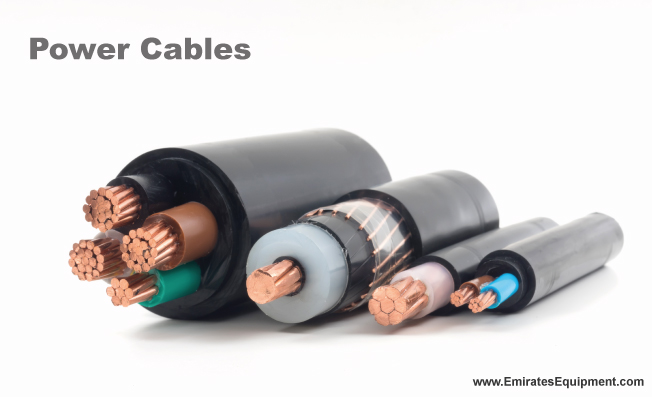

Power cables are an essential part of our modern technological world. They are used to connect electronic devices and provide power to them. However, not all power cables are the same. There are different types of power cables with different specifications and uses. In this blog post, we will discuss the various types of power cables and their uses.

Unshielded Twisted Pair (UTP)

Unshielded Twisted Pair (UTP) is a type of cable that consists of two conductors twisted together to reduce interference. UTP cables are commonly used for network applications, such as Ethernet connections. They are also used for telephone lines and audio applications.

UTP cables are cost-effective and easy to install. However, they have some limitations. They have a shorter range compared to other cable types and are susceptible to interference from other electrical devices.

Shielded Twisted Pair (STP)

Shielded Twisted Pair (STP) is a type of cable that has a metallic shield around the conductors to reduce electromagnetic interference (EMI) and radio frequency interference (RFI). STP cables are commonly used for high-speed data applications, such as data centers and server rooms.

STP cables provide better protection against interference than UTP cables. However, they are more expensive and difficult to install.

Coaxial Cable

Coaxial Cable is a type of cable that consists of a central conductor surrounded by a dielectric insulator and a metallic shield. Coaxial cables are commonly used for cable TV, satellite TV, and high-speed internet connections.

Coaxial cables provide better signal quality than UTP cables and can transmit signals over longer distances. However, they are more expensive and difficult to install.

Fiber Optic Cable

Fiber Optic Cable is a type of cable that uses light to transmit signals. Fiber optic cables are commonly used for high-speed data applications, such as telecommunications and data centers.

Fiber optic cables provide the best signal quality and can transmit signals over longer distances than other cable types. However, they are the most expensive and difficult to install.

Power Cords

Power Cords are a type of cable that is used to connect electronic devices to a power source. Power cords are commonly used for laptops, desktop computers, and other electronic devices.

Power cords are easy to install and provide a simple solution for powering electronic devices. However, they have a limited range and cannot be used for data transmission.

How to Choose the Right Power Cable When selecting a power cable, there are several considerations to keep in mind. The first consideration is the type of cable that is needed. Depending on the application, different cable types may be required. The second consideration is the length of the cable. The cable should be long enough to reach the device, but not too long as it can result in signal loss. Finally, it is important to choose a cable that is appropriate for the environment. For example, if the cable will be exposed to moisture, a waterproof cable may be necessary.

Insulated power cables

Insulated power cables are used to transmit electrical power from one point to another. These cables are designed to provide a safe and reliable means of power transmission, while also protecting the cable from environmental factors. In this blog post, we will discuss different types of insulated power cables.

- PVC Insulated Cables

PVC insulated cables are the most commonly used insulated power cables. They are made of copper or aluminum conductors with a PVC (Polyvinyl chloride) insulation. PVC is a good insulator and provides protection against moisture, chemicals, and sunlight. These cables are easy to install and are suitable for indoor and outdoor applications.

- XLPE Insulated Cables

XLPE (Cross-linked polyethylene) insulated cables are designed to withstand higher temperatures and voltages than PVC insulated cables. The insulation is made of a thermoset material that can withstand temperatures up to 90°C. These cables are ideal for use in underground power distribution and industrial applications.

- Rubber Insulated Cables

Rubber insulated cables are designed to withstand harsh environmental conditions. The insulation is made of a rubber material that can withstand temperatures up to 90°C. These cables are commonly used in industrial applications where flexibility and durability are required.

- Mineral Insulated Cables

Mineral insulated cables (MIC) are designed for use in high-temperature applications where fire resistance is essential. These cables are made of copper conductors with a mineral insulation that can withstand temperatures up to 950°C. MIC cables are commonly used in power plants, chemical plants, and other industrial applications where fire resistance is essential.

- Paper Insulated Cables

Paper insulated cables are an older type of cable that is no longer commonly used. The insulation is made of paper impregnated with oil or wax. These cables are suitable for low voltage applications and are commonly found in older buildings.

In conclusion, insulated power cables are essential components of any electrical power system. PVC, XLPE, rubber, mineral, and paper insulated cables are all types of insulated power cables that have their unique advantages and disadvantages. Selecting the right type of cable depends on factors such as the application, environment, and temperature requirements. It is important to consult with a qualified electrician or engineer to ensure that the appropriate cable is selected for the specific application.

Selecting the Right Cable Gauge

Choosing the right gauge of cable for your load is crucial in ensuring that the cable can safely and efficiently carry the electrical current required by the load. In this blog post, we will discuss how to select the right gauge of cable based on your load.

Understanding Wire Gauge

Wire gauge refers to the diameter of the wire. The larger the diameter, the lower the gauge number. For example, a 12-gauge wire has a larger diameter than a 14-gauge wire. The American Wire Gauge (AWG) system is used to measure wire gauge.

Current Load and Cable Gauge

The amount of current that a cable can safely carry is determined by its gauge. A thicker wire can carry more current than a thinner wire. It is important to select a cable gauge that can safely handle the current required by the load.

To determine the current load of your device, you can check the specifications of the device or consult an electrician. Once you know the current load, you can use a wire gauge chart to determine the appropriate wire gauge.

Wire Gauge Chart

A wire gauge chart shows the appropriate wire gauge for a given current load. Here is a wire gauge chart for reference:

- 20 AWG – 0.5 amps

- 18 AWG – 1.0 amps

- 16 AWG – 1.5 amps

- 14 AWG – 2.0 amps

- 12 AWG – 3.0 amps

- 10 AWG – 5.0 amps

- 8 AWG – 8.0 amps

- 6 AWG – 12.0 amps

- 4 AWG – 20.0 amps

- 2 AWG – 30.0 amps

- 1 AWG – 40.0 amps

- 0 AWG – 50.0 amps

Wire gauge chart with square millimeter sizes

- 0.5 mm² – 0.25 amps

- 0.75 mm² – 0.5 amps

- 1.0 mm² – 0.75 amps

- 1.5 mm² – 1.5 amps

- 2.5 mm² – 3.0 amps

- 4.0 mm² – 6.0 amps

- 6.0 mm² – 10.0 amps

- 10.0 mm² – 16.0 amps

- 16.0 mm² – 25.0 amps

- 25.0 mm² – 35.0 amps

- 35.0 mm² – 50.0 amps

- 50.0 mm² – 70.0 amps

Note that the conversion from AWG to square millimeters is not exact, as the AWG system is based on the wire’s diameter in mils (1/1000 of an inch), while the square millimeter sizes are based on the wire’s cross-sectional area in square millimeters. Nonetheless, this chart should provide a useful reference for selecting the appropriate cable gauge for your load.

To select the right cable gauge for your load, you need to determine the maximum current that your device requires. Once you know the maximum current, you can refer to the wire gauge chart to find the appropriate wire gauge.

It is important to note that if the wire gauge is too small for the load, the cable can overheat, which can cause damage to the device or even a fire. On the other hand, if the wire gauge is too large, it can be unnecessary and more expensive.